Grouped plain V-belts

Classification:

Introduction

| Type | Pitch | Top width | Height | Angle | Length conversion | Length range (inches) | Length range (mm) | Coefficient marker |

| AJ | 15.6 | 13.6 | 10.0 | 40° | Li=La-63 | 55"-100" | 1397-2540 | Li |

| BJ | 19.0 | 17.0 | 13.0 | 40° | Li=La-62 | 55"-200" | 1397-5080 | Li |

| CJ | 25.5 | 22.4 | 16.0 | 40° | Li=La-100 | 80"-300" | 2000-12500 | Li |

| DJ | 37 | 32.8 | 21.5 | 40° | Li=La-135 | 177"-300" | 2000-12500 | Li |

Features

The joint group of ordinary V-belts is connected by a plurality of ordinary V-belts through a connecting layer to make it a whole. When driving, it can eliminate the disadvantages of vibration, slapping and belt turning in each single operation, and make each belt bear uniform force and can bear large load.

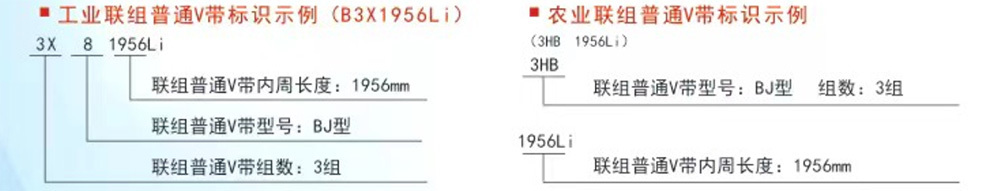

Identification

The identification sequence of common V-belts in groups is model, number of groups, length size and length identification. The company identifies them according to the inner circumference length of the V-belt. The conversion relationship of each model is shown in the table above.

Grouped plain V-belts are an essential component in many mechanical power transmission systems. These belts are designed to efficiently transfer power between rotating shafts.

One of the key characteristics of grouped plain V-belts is their flexibility. This flexibility allows them to adapt to the various pulley configurations commonly found in industrial machinery. They can easily wrap around pulleys of different sizes and shapes, enabling smooth power transmission.

Grouped plain V-belts are typically made from high-quality materials that can withstand the rigors of continuous operation. These materials are chosen to resist wear and tear, ensuring a long service life. This durability is crucial in industrial settings where machinery often runs for extended periods without interruption.

The grouped belts work together to distribute the load evenly across multiple belts. This helps in handling higher power requirements compared to a single V-belt. The proper grouping ensures that each belt shares the load proportionally, reducing the risk of individual belt failure due to overloading.

In terms of efficiency, grouped plain V-belts offer a high level of power transmission efficiency. They are engineered to minimize power losses during the transfer process. This efficiency is beneficial for reducing energy consumption in industrial operations, which can lead to cost savings in the long run.

The installation of grouped plain V-belts is relatively straightforward. They can be easily installed onto the pulleys, and proper tensioning can be achieved without excessive complexity. This ease of installation makes them a popular choice in many manufacturing and industrial applications.

Moreover, these V-belts are available in different sizes and specifications. This allows for customization based on the specific requirements of different machinery. Whether it's a small-scale equipment or a large industrial machine, the appropriately sized grouped plain V-belts can be selected.

Key words:

Grouped plain V-belts

Previous:

Related Products

Inquiry