Grouped plain power V-belts

Classification:

Introduction

| Type | Pitch | Top width | Height | Angle | Length conversion | Length range (inches) | Length range (mm) | Coefficient marker |

| AJ | 15.6 | 13.6 | 10.0 | 40° | Li=La-63 | 55"-100" | 1397-2540 | Li |

| BJ | 19.0 | 17.0 | 13.0 | 40° | Li=La-62 | 55"-200" | 1397-5080 | Li |

| CJ | 25.5 | 22.4 | 16.0 | 40° | Li=La-100 | 80"-300" | 2000-12500 | Li |

| DJ | 37 | 32.8 | 21.5 | 40° | Li=La-135 | 177"-300" | 2000-12500 | Li |

Features

The joint group of ordinary V-belts is connected by a plurality of ordinary V-belts through a connecting layer to make it a whole. When driving, it can eliminate the disadvantages of vibration, slapping and belt turning in each single operation, and make each belt bear uniform force and can bear large load.

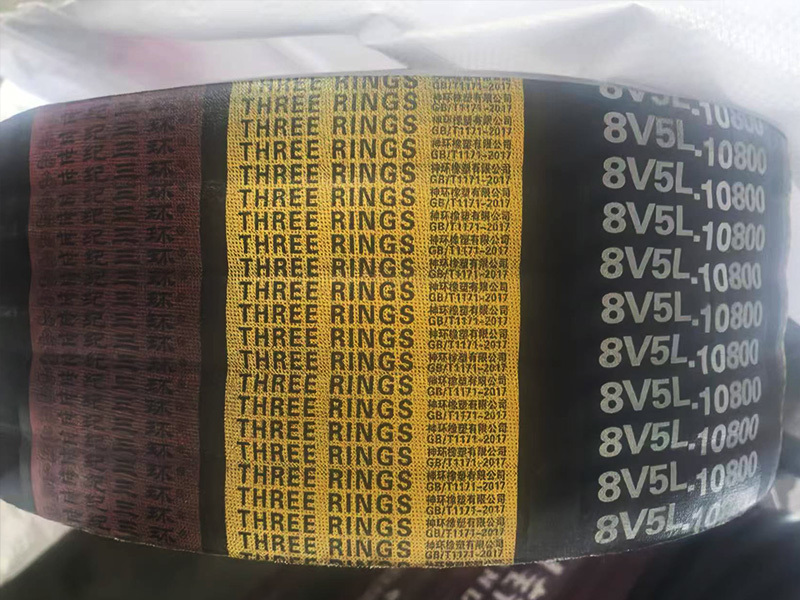

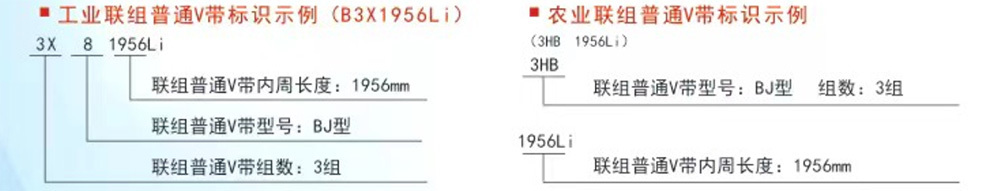

Identification

The identification sequence of common V-belts in groups is model, number of groups, length size and length identification. The company identifies them according to the inner circumference length of the V-belt. The conversion relationship of each model is shown in the table above.

Grouped plain power V-belts represent a cornerstone of modern mechanical drive systems, designed to deliver reliable and efficient power transmission across diverse industrial applications. These belts are engineered to meet the demands of high-performance machinery, combining advanced materials with innovative structural designs to ensure optimal performance in challenging environments. By prioritizing durability, flexibility, and precision, grouped plain power V-belts have become indispensable in sectors ranging from manufacturing to agriculture.

At the heart of these belts lies a robust composition featuring high-grade rubber compounds reinforced with polyester or aramid cords. This blend ensures exceptional tensile strength, minimizing stretch and maintaining dimensional stability under heavy loads. The "grouped" design refers to the strategic arrangement of multiple belts within a single drive system, allowing for balanced load distribution and reduced vibration. This configuration not only extends service life but also enhances overall system efficiency by preventing uneven wear.

Grouped plain power V-belts excel in maximizing power transfer through their trapezoidal cross-section, which optimizes contact with pulley grooves. This geometry reduces slippage and ensures consistent energy transmission, even at varying speeds or torque levels. Compared to traditional flat belts, this design achieves up to 98% efficiency, translating to lower energy consumption and reduced operational costs. Their ability to operate smoothly at high rotational speeds further solidifies their suitability for demanding applications such as conveyor systems, compressors, and heavy-duty pumps.

Industrial environments often expose machinery to extreme temperatures, oil, dust, and moisture. Grouped plain power V-belts address these challenges with specialized coatings and heat-resistant rubbers that resist cracking, hardening, and degradation. Their construction also includes reinforced edges to prevent fraying, ensuring prolonged functionality in abrasive settings. This resilience minimizes downtime and maintenance intervals, making them a cost-effective solution for continuous-operation industries like mining and cement production.

Their standardized dimensions simplify replacement processes, while the grouped configuration allows for quick alignment and tensioning adjustments. This user-friendly design reduces installation time and minimizes the risk of misalignment, a common cause of premature belt failure. Additionally, their compatibility with standard pulley sizes ensures seamless integration into existing machinery, eliminating the need for costly equipment modifications.

Key words:

Grouped plain power V-belts

Previous:

Next:

Related Products

Inquiry