Joint group narrow-section V-belt

Classification:

Introduction

| Type | Pitch | term width | Height | Angle | Length conversion | Length range (inches) | Length range (mm) | Identification standard |

| 3V(9J) | 10.3 | 9.7 | 9.7 | 40° | La = Li 63 | 47 "-100" | 1200-5040 | La |

| 5V(15J) | 17.5 | 15.7 | 15.7 | 40 | La = Li 98 | 59"-200" | 1500-5080 | La |

| 8V(25J) | 28.6 | 25.4 | 25.4 | 40° | The = Li 157 | 79"-300" | 2000-7262 | La |

| SPZ | 10.0 | 10.0 | 40° | La = Li 63 | 47"-100" | 1200-2540 | La | |

| SPA | 12.3 | 12.3 | 40° | La = Li 78 | 47"-100" | 1200-2540 | La | |

| SPB | 16.5 | 16.5 | 40° | La = Li 105 | 59"-200" | 1500-5080 | La | |

| SPC | 21.0 | 21.0 | 40° | La = Li 132 | 118"-300" | 3000-7620 | La |

Features

The group of narrow V-belts is connected by a plurality of narrow V-belts through a connecting layer to form a whole. When driving, it can eliminate the disadvantages of vibration, slap and belt turning in the operation of each single belt, and make each belt bear uniform force and can bear large load.

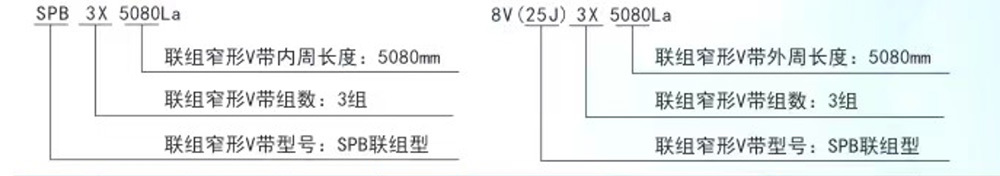

Identification

The identification sequence of the narrow V-belt of the group is model, number of groups, length size and length identification. The company identifies the V-belt according to the outer length of the V-belt. If the customer has special requirements, it should be indicated on the list of goods. The conversion relationship of each model is shown in the table above.

Identification Example

The narrow-section design of Joint Group Narrow-Section V-Belts for a higher power-to-space ratio. Compared to traditional V-belts, they can transmit up to three times the horsepower in the same drive space. This is achieved through their unique cross-sectional shape, which provides enhanced traction and torque transmission. The narrow-section profile, with a width-to-height ratio optimized for power transfer, enables the belts to wedge more effectively into the pulley grooves as the load increases. As a result, they can handle heavier loads and higher speeds, making them ideal for applications where space is limited but high-power output is required.

Enhanced Durability

Constructed with high-quality materials, joint group narrow-section V-belts are built to last. The tensile cords are made of extra-strong polyester, which is treated to resist fatigue and stretching. This not only ensures exceptional length stability but also contributes to the overall drive uniformity. The cover fabric has a special bias-cut angle, which reduces stress as the belt bends around the sheaves. This minimizes heat build-up, a common cause of premature belt failure, and thus extends the service life of the belt. The rubber compound used in the body of the belt is engineered to maintain structural integrity while providing the necessary flexibility to adapt to different operating conditions.

Wide Range of Applications

These belts find extensive use in a variety of industries. In the manufacturing sector, they are commonly employed in small electric tools, where their compact size and high-power transmission capabilities are highly valued. In the food machinery industry, they ensure smooth and reliable operation, meeting the strict hygiene and safety standards. They are also widely used in fishing boats, providing the necessary power for various on-board equipment. In the energy industry, they play a crucial role in power generation and transmission systems. Additionally, they are suitable for use in snowplows, agricultural machinery, construction machinery, and mining machines, where they can withstand harsh operating conditions and heavy loads.

Joint Design Benefits

The joint group design of these V-belts offers several advantages. By joining multiple individual belts together, the belts can better distribute the load, ensuring that each belt in the group bears an equal share of the force. This not only improves the overall performance of the belt drive but also extends the lifespan of the belts. The joint design also helps to reduce vibration and noise, resulting in a smoother and quieter operation. Moreover, it simplifies the installation process, as there is no need to match multiple single belts.

Key words:

Joint group narrow-section V-belt

Previous:

Next:

Related Products

Inquiry